Customer Support

Can do. Will do.

Our TECHNICAL and EQUIPMENT Service Representatives are at your service to provide support for every aspect of your can manufacturing process. Their involvement begins with a final can design and continues all the way through to the secondary packaging operation.

- Around-the-clock seamer service

- 20+ years average experience per technician

- Answers to regulatory compliance, food safety, and materials questions

- Click this link for detailed information on our Equipment and Technology Services Fees.

TECHNICAL SERVICES

Supporting customers around the clock.

Our Technical Service Representative (TSR) Group provides routine visits, advice, and testing to ensure your technical needs are continually exceeded.

SERVICES INCLUDE:

- Monitor container performance within the customer’s empty and filled can handling and processing systems.

- Update customer contacts on new container development, materials specification changes and all other technical issues.

- Review/investigate any quality issues encountered by customers.

- Assist in development of new specifications appropriate for customer products.

- Provide technical assistance for first-time use and qualification of cans and ends.

- Coordinate ongoing evaluation of packed product to verify performance (test packs).

- Assist customer R&D, Packaging, Operations or QA personnel with questions posed by state and federal government inspectors regarding the use of Silgan packages.

- Coordinate responses from multiple Silgan departments for various audits required by customers (SQF, GFIC, etc).

- Develop retort operating procedures (vent schedules) for still, steam retorts.

- Establish proper and safe time/temperature thermal processes for still, steam retorted products including the determination of critical factors and other process parameters.

- Provide thermal process deviation evaluations for customers operating in a still, steam retort situation.

- Consult with customers on a variety of process-related issues such as proper cooling, chlorination of cooling water, container reactions to abnormal physical conditions or process equipment operation.

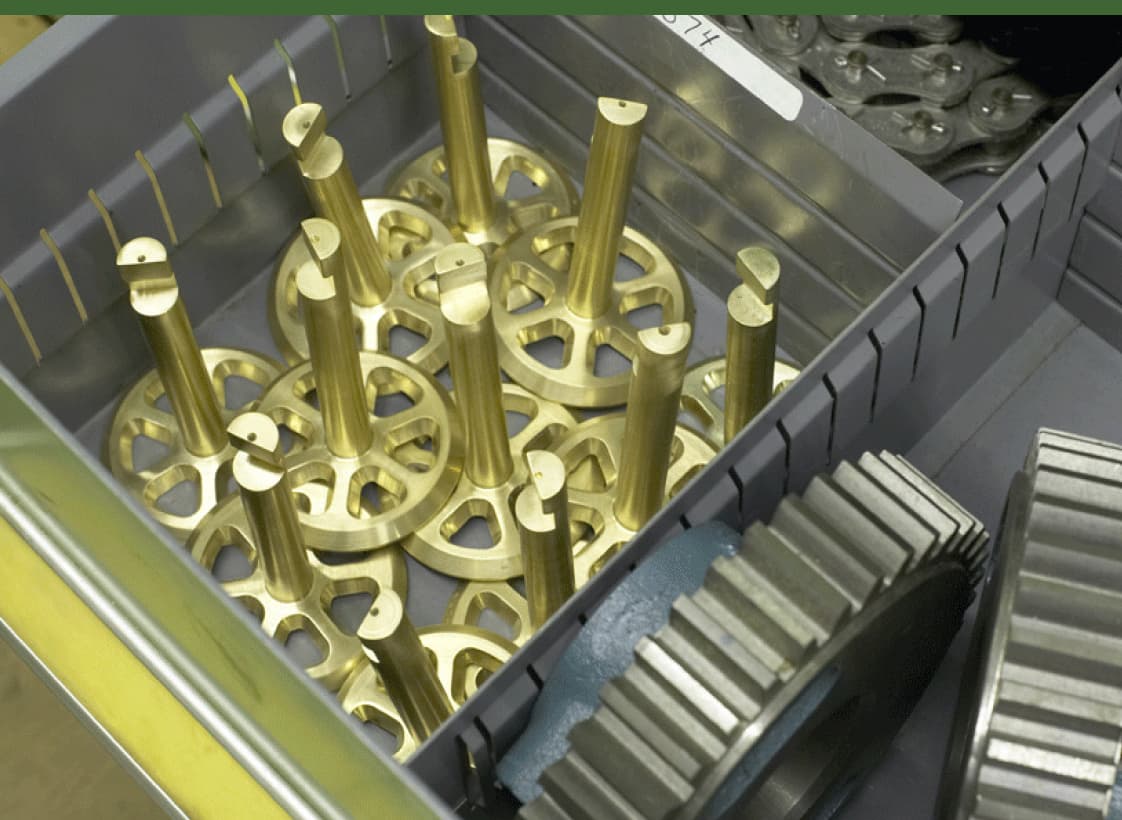

Parts & Equipment

Services

Our customer Equipment Service Representatives provide on-site assistance to help ensure smooth installation of OEM Canco parts.

To request a parts quote, please contact Darren Larson at Djlarson@silgancontainers.com or call 262-569-5293

Equipment Services

Keeping your operations in running order.

Our Customer Equipment Services (CES) Group of highly-trained individuals works closely with management, maintenance and quality control to ensure your process is always running.

Services include:

- CES reps perform and/or review Double Seam (DS) evaluations for each line that is running.

- Recommendations are made for any deficiencies identified by the DS evaluation.

- CES reps assist with closing machine issues and Double Seam deficiencies.

- CES reps assist with performance of audits.

- CES reps assist with overhaul and repairs.

- 1–3 days (depending on number of lines and configuration). Recommendations are recorded for any deficiencies that are identified.